Recyclable Materials

As a leading pioneer in green manufacturing, Living Fountain has been dedicated for years to researching various eco-friendly plastic materials. We insist on using the safest and sustainably valuable plastic raw materials to create a full range of environmentally friendly and stylish tableware.

Sustainable Production

Living Fountain aligns with the 12th goal of 17 SDGs (Sustainable Development Goals) - ensuring sustainable consumption and production patterns. We integrate green sustainability into our company's operational plans and continue to move towards "green energy" and "energy saving and carbon reduction" in our production.

Renewable Energy

Living Forward has installed a solar power generation system to generate clean and renewable energy. The solar panel installation capacity is 97.905 kilowatts, and the total renewable energy power generation in 2021 is 123,419 kWh, reducing carbon emissions by 62,820 kilograms. In 2020, the total power generation from renewable energy was 126,454 kWh, reducing carbon emissions by 63,480 kilograms.

Energy Saving and Carbon Reduction

The traditional hydraulic injection machine is driven by the mains power (220V/60Hz) and uses a quantitative pump to supply oil to a three-phase induction motor. Energy consumption is generated due to the continuous operation of the three-phase induction motor and the function of the relief valve. Using an all-electric injection molding machine can not only increase the original output, but also reduce the power consumption to 0.435 times the original, saving 56.5%.

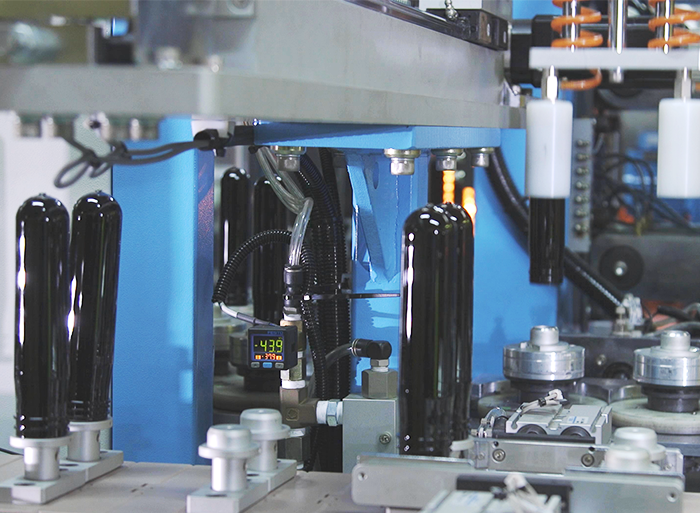

Energy Saving and Carbon Reduction

Adjusting the position of the light tubes in 14 bottle-blowing machines' original settings can result in approximately 13.7% energy savings.

Energy Saving and Carbon Reduction

Climate Action

ESG stands for Environmental, Social, and Governance, representing the acronym for Corporate Social Responsibility. While Living Fountain continues its ongoing operations, it strives to embrace the principles of ESG sustainability, contributing to society, addressing environmental concerns, and creating a better future for all.

Social Welfare

01

Living Forward felt that the epidemic was serious and affected our health and safety. Together with the legislators, we donated a "Positive Pressure Quarantine Booth" to our neighbor in the Chenggong Factory in Dali District: Dali Wufeng Chengcheng Hospital, hoping to reduce the number of residents Move across regions, contribute to the prevention and control of the epidemic, and jointly protect the country.

Social Welfare

02

Living Forward and local enterprises jointly responded and donated solar-powered LED strobe lights to Wufeng District. The LED strobe lights are powered by solar photovoltaic panels and automatically light up after nightfall. They are installed at important intersections in Wufeng District, areas prone to accidents and It can effectively remind passers-by to pay attention to safety in dimly lit and other turning sections.

Social Welfare

03

Living Forward participate in the 2023 Love the Earth Beach Cleaning and Plastic Reduction Event co-organized by the Taichung City Plastic Products Business Association and the Changhua County Plastic Products Business Association, and sponsored by Hongen Group. It was held grandly at the Changbin Small Fishing Port. Hundreds of people enthusiastically participated in loving the Earth on the beach. Clean beach.

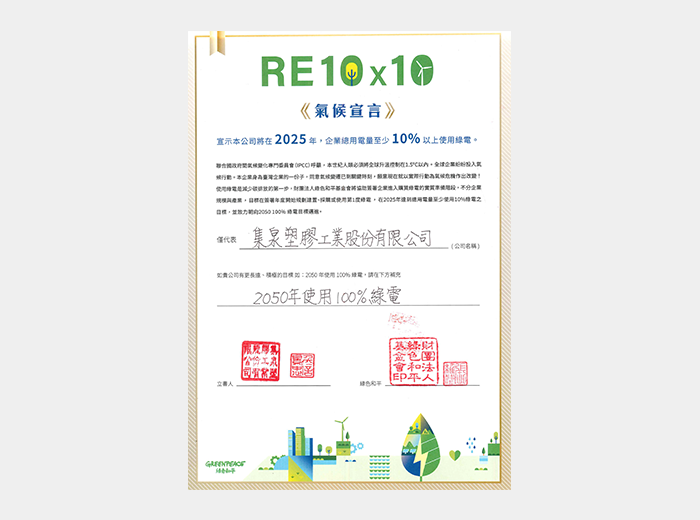

RE10x10 Climate Declaration

04

To accelerate the carbon reduction efforts of Taiwanese companies and demonstrate a commitment to addressing the climate crisis, Greenpeace has launched the “RE10x10” initiative. On August 24, 2022, Living Fountain signed the "RE10x10 Climate Declaration," pledging to achieve a minimum of 10% green energy usage in total electricity consumption by 2025 and striving towards 100% renewable energy usage by 2050.

LED Panel Lights Installation

05

All types of lights in the entire factory, totaling 779 bulbs, have been completely replaced with LED panel lights. It has decreased from 41,649 to 31,669 watts, reducing usage by approximately 24% in total.

Reusable PP Corrugated Boxes

06

Gradually replacing single-use cardboard boxes in the factory with reusable PP corrugated boxes. This change reduces the use of approximately 36,924 paper boxes per year, resulting in a carbon emission reduction of 337,855 kilograms.

Paperless Office

07

From June 2022 to May 2023, a total of 35,831 electronic documents were processed, saving 644.958 kg of carbon emissions.

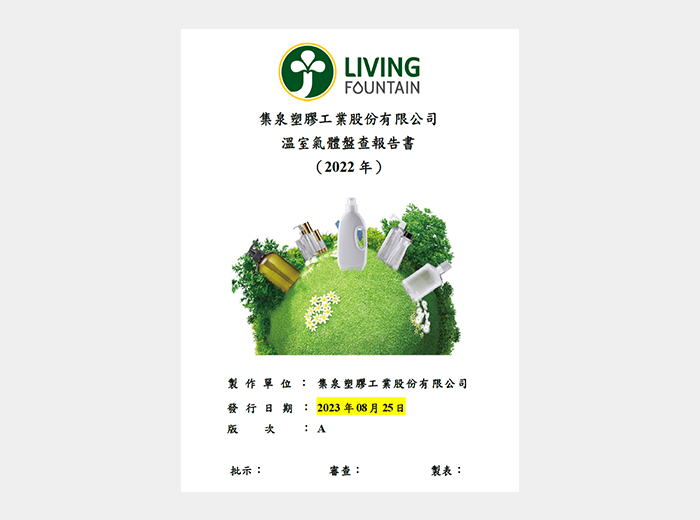

Carbon Footprint Verification On-going

08

Since April 2023, the entire plant has been undergoing guidance for the ISO 14064-1 carbon footprint verification, with the verification expected to be completed by the first quarter of 2024. The Greenhouse Gas(GHG) inventory report for the year 2022 has already been generated.